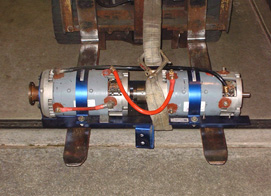

Pulled the twin motor drive unit out of the car and converted the two 8 inch motors into world's first 'Siamese 8'.

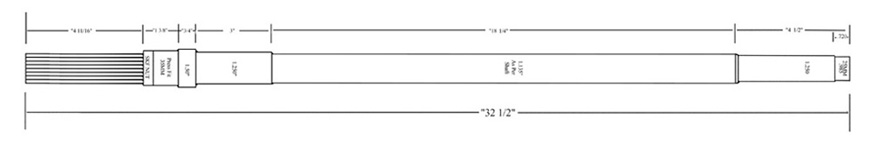

The two motors were torn down and all parts were rebuilt. Next, various hot rod tricks were applied, new parts were designed and created, and after motor artisan Jim Husted of 'Hi-Torque Electric' and Plasma Boy came up with a plan, a custom extra-long stainless steel shaft was fabricated by 'Dutchman Motorsports'. Below is an early drawing of the proposed extra-long motor shaft required to make the Siamese 8 motor possible.

The two armatures were conjoined at their heads as they were pressed onto the new shaft with their respective commutator ends at the far ends of the shaft, who's large splined output end mates into the female splines of the new aluminum driveshaft.

Direct drive. No reverse.

Replaced two piece steel driveline with its center carrier bearing, to a new large diameter single piece all aluminum driveline from 'Inland Empire Drivelines'. Driveline loop.

Dutchman heavy duty Street-strip Ford nine inch rear axle setup with 31 spline racing axles, 4:57 gears and Detroit locker. Air shocks & traction bars.

Front - Eagle 5 spoke 13 x 5.5 alloys with 4 bolt Nissan rear drive offset and 175/50/13 Nitto Exit GS radials.

Rear - Eagle 5 spoke 14 x 6 alloys with 5 bolt Ford front drive offset and BF Goodrich 'TA Drag Radials' (24" dia.)

Removed and replaced the 24 Orbitals @ 288V with 29 smaller 12 volt, 24.5 lb. Hawker 'Aerobatteries' 26 ahr @ 348V nominal, 710 lbs. total pack weight. The original rear seat area enclosure that had been in the car since '98 had finally outlived its usefulness and was removed. (center) An all new tray was designed and built to hold the new batteries. (right) A new base plate and new hold-downs were made to secure the rear batteries into the sunken well area.

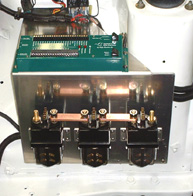

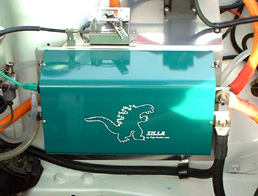

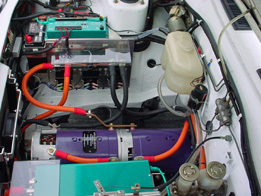

Removed and replaced the Godzilla 1400 amp controller with Cafe Electric's new 'Zilla' 2000 amp controller (left) and Hairball interface (right) featuring programable automatic series-parallel contactor control. The aluminum plate that held the Godzilla 1400 amp controller and bridged over the previous dual motors between the two strut towers was removed. The new Siamese 8 electric motor (center) is in full view with easy access. The new Zilla Z2K controller (right) is now mounted on an aluminum bracket mounted to the right fender inner panel, while the 'Hairball' interface and the three series-parallel contactors (left) are on a mirror image bracket on the left fender inner panel. At the time of the eft and center photos, the Hairball and contactors wiring had not yet been done and the controller was not yet wired up. The high current motor bus bars and cables shown in the center photo were later changed to the different wiring scheme as shown in the rightmost photo under the above 'Motor:' category.

One of the advantages of the Hairball & Zilla combination, is the ability to capture data and plot it to see how the car's electric traction system is performing. The graph below clearly shows how the battery pack reacts to the heavy loading of the Zilla controller, where the motor sections wiring shift from Series to Parallel occurs (peak 1/4 across the graph), and other vital information.

Due to the new location of the controller, it's cooling tank and pump was relocated to the firewall location.

The factory 12V starting battery mount that had held the twin small Exide 12V batteries was cut-away to make room for the new aluminum mount plate that holds the Hairball Interface. A single 8 year old (still in great condition with 12.85 static volts) 13.5 lb. Hawker Genesis 16EP 12V 16 ahr battery replaced the previous pair of 12V batteries and was located at the leading area of the new mount plate:

We also removed the 1st gen. 20 amp Todd PC20-LV DC-DC as it was unable to operate even at 1/2 the new pack's voltage. A second generation Todd 30 amp model DC-DC converter was modified to run at 336V input and installed on the behind-the-seatback-bulkhead aluminum plate. The blue and green (with the tacky yellow crimp style butt splice connector) wires were internally connected (soldered after the converter's voltage doubler to the high voltage caps.) then routed outside and connected to the 348V battery pack.

2416 lbs. (est)

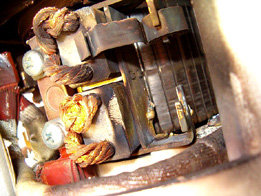

Zorched a brush holder due to a flash-over incident during the burnout at Woodburn. Take a look at the left area under the Zombie's nose in this photo from that memerable burnout, and you can clearly see how the flash-over illuminated the pavement! Though there was way too much wheel spin off the line, Tim Brehm still pulled off a nice 12.65 @ 104 mph run with just 7 of the Siamese 8's total number of 8 brushes making contact with their respective commutator bars. Photo on right is a close-up of the rear motor section's brush end bell and the effects of the vaporized brush spring incident.